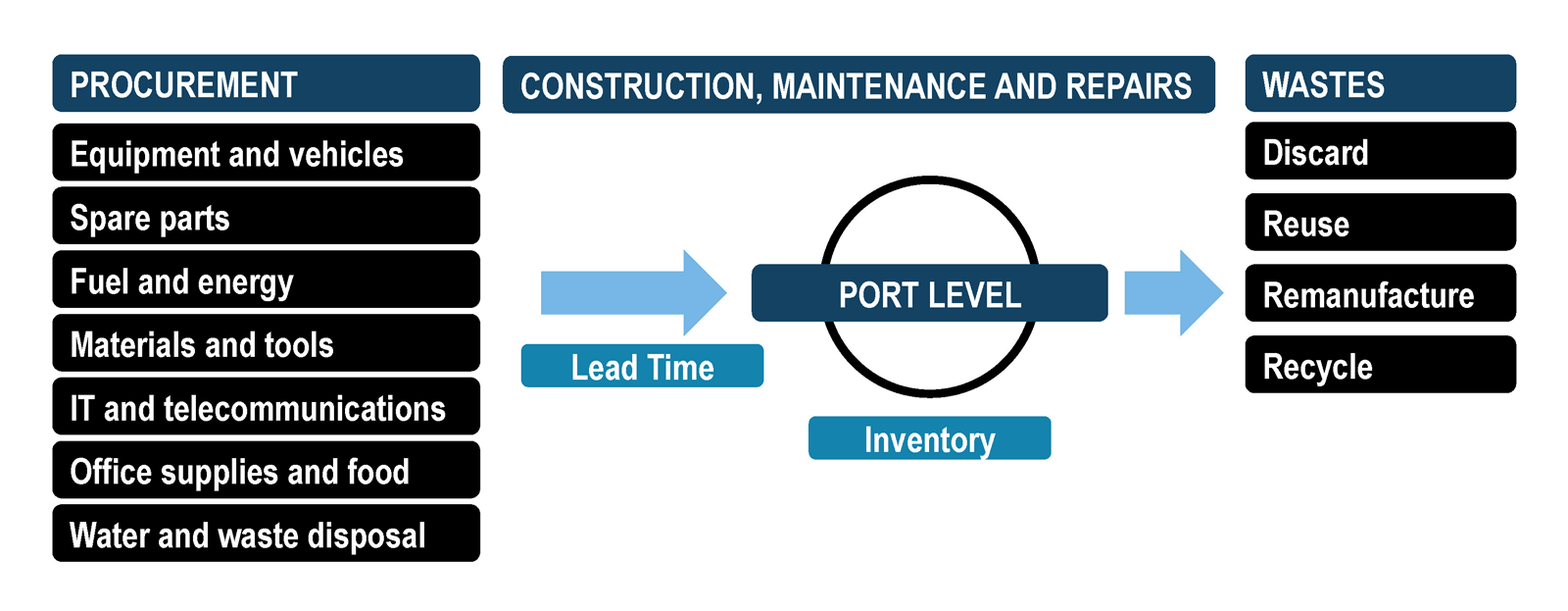

Ports not only support supply chains but also need to ensure the smooth functioning of their own supply chains; the latter requires a procurement process which can supply ports and terminals with: (i) construction material; (ii) maintenance and repair of equipment; (iii) supply spare parts, energy; and (iv) other essential items to maintain operations (figure 11). These supply chains are provided by third parties and can be subject to disruptions, which would compound their impact and undermine port resilience. Port activities also generate wastes that need to be processed, recycled and discarded.

Figure 11: Third-party suppliers supporting port operations

Each element relating to third-party suppliers has a lead time, and procurement needs to allow for sufficient time to ensure access to required supplies (e.g. goods and services). For some procurement, the lead time can take years, whereas some utilities, e.g. electricity and water, can be supplied in real-time. For instance, once ordered from a manufacturer, a crane can take up to two years to be delivered. The port maintains an inventory level that should allow for the rapid repair or replacement of defective components, so that operations can be maintained. If a component is not available and has a long lead time, a disruption could endure for as long as the component has not been replenished.

The financial strength of third parties, such as port subcontractors and suppliers, can also be an indicator if they are solvent and robust, should a disruptive event occur. Relying on multiple suppliers and sources is a possible port resilience strategy, but every additional supplier brings additional negotiating and contracting costs. Another approach when a port is facing third-party risk or uncertainty is to hold buffer or safety stocks at the port, or at a convenient local storage facility. A buffer stock is the level of extra inventory maintained to mitigate risk due to uncertainties or events which may alter the demand for, or supply of, port operations. Third-party suppliers need to be agile and can contribute to resilience by, for example, offering procurement options and having a presence in a port’s hinterland.

Finally, port activities generate waste, including discarded parts and equipment, that must be appropriately handled. Resilience can involve the capability of a port to discard, re-use, re-manufacture or recycle its waste.