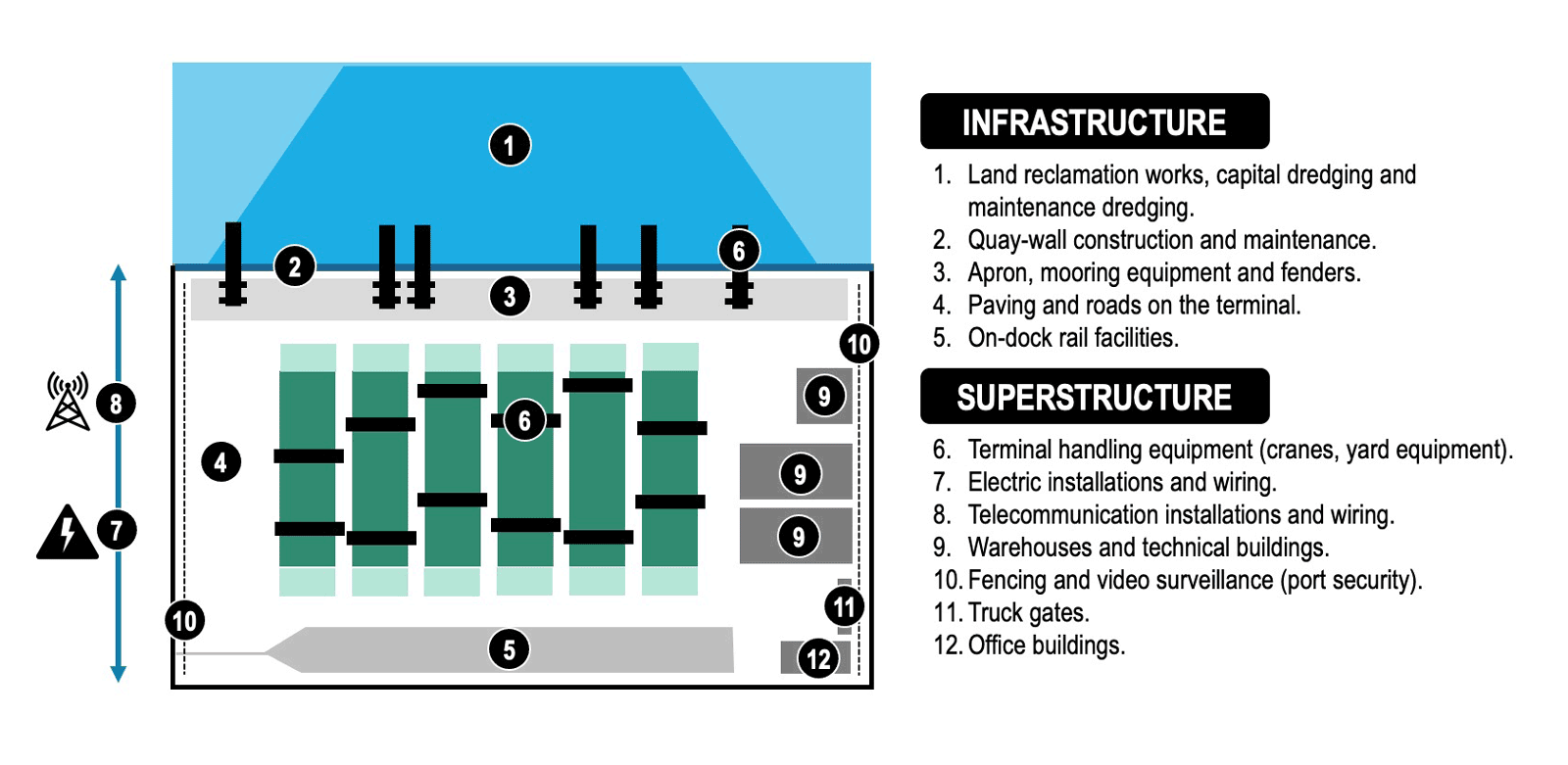

Physical port resilience allows withstanding natural hazards, e.g. earthquakes and anthropogenic risks, from accidents or hazardous materials. Existing infrastructure and superstructure can be hardened with design features capable of withstanding physical damage resulting from natural hazards, e.g. extreme weather events and earthquakes (figure 35).

Figure 35: Strengthening of port terminal infrastructure and superstructure

Source: T. Notteboom et al (2022).

The main infrastructure and superstructure components that can be hardened include:

- Land reclamation works. Ensuring that the terminal facility is on stable foundations that are less vulnerable to erosion and landslides. This includes breakwaters able to protect the port from current and tidal effects.

- Dredging of access channels and basins. Ensuring that the nautical profile of the port can accommodate a diversity of ship sizes and classes. Having an access channel less vulnerable to blockage.

- Quay-wall construction and maintenance. Ensuring that quay walls can handle additional tidal, seismic stresses and small collisions.

- Apron, mooring equipment and fenders. Ensuring that the dock can moor and secure ships under stressful conditions (e.g. high wind, tides).

- Terminal handling equipment. Ensuring that terminal equipment, such as ship-to-shore cranes, gantry cranes, and yard equipment, can withstand expected natural hazards and can be repaired quickly in case of damage, breakage or failure. Availability of equipment (and work shifts) to handle demand surges.

- Electric installations and wiring. Strengthening of the electric distribution system, particularly towards crucial equipment and facilities. Setting auxiliary power generation.

- Telecommunication installations and wiring. Strengthening of the wired and wireless telecommunication system. Installation of a backup telecommunication system.

- Paving of the terminal. Ensuring a hardened well-drained terminal surface, particularly yard areas.

- On-terminal rail facilities (if present). Ensure rail yards and spurs can withstand expected natural hazards.

- Roads on the terminal. Ensuring that areas across the terminal remain accessible and that alternate routes are available.

- Warehouses and technical buildings. Ensuring that buildings can withstand a range of expected natural hazards.

- Fencing and video surveillance. Ensuring that the port perimeter remains a secure facility with controlled access.

- Truck gates and inspection. Ensuring that terminal access for drayage, supplies and the workforce remains available, including alternate access points.

- Office buildings. Ensuring that buildings can withstand a range of expected natural hazards and that they are able to provide on-site business continuity for management and the workforce.

As an outcome, robustness is improved, and infrastructure and superstructure are less susceptible to damage from high winds, flooding, storm surges, flying debris or tremors. Existing infrastructure and superstructure need to be stress-tested to see if they can withstand stress levels associated with a range of expected natural hazards. This can also include simulations where the facility and its equipment are submitted to exceptional circumstances. These results would shed light on the condition of a particular infrastructure (or superstructure) if it were to experience stress, particularly if it remains operational. As some infrastructure and superstructures are already designed to meet industry and regulatory standards, it is necessary to ensure that this remains the case, particularly as they age.